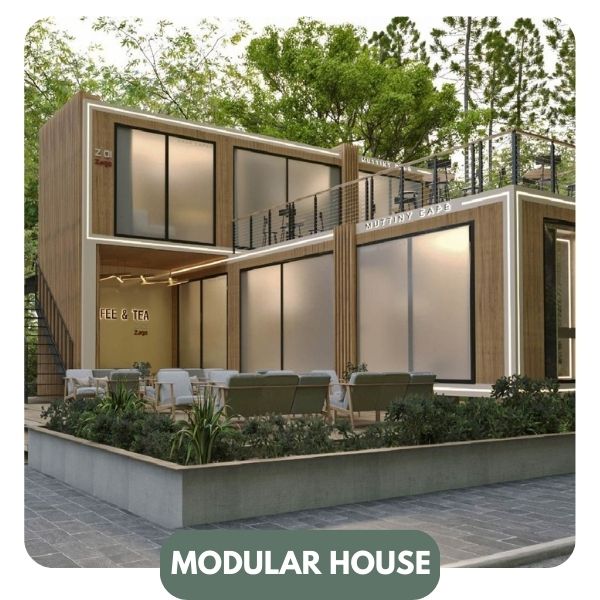

Modular Building Delivery

We cooperate with the most experienced moving companies to make sure your Prefab buildings will be delivered safely and on time. Prefabturkey take the hassle away from you when it comes to delivering prefab buildings. That’s because we manage the entire process, from transporting it to expert installation. We’ll design a specific plan for your prefab building delivery, taking into account the different factors. These include restricted access sites, health & safety regulations, sites of sensitive nature and remote locations.